It is one of the machines with the greatest tradition and presence in machining workshops around the world, but really. How much do we know about this type of machines?

Although its origins go back to the century s. IX AC, is not until the thirteenth century, when they acquire obvious advantages for its operation and operation: they go from being exclusively manual management systems, to being handling equipment through a pedal. It is from s. XV, when they appear lathes of transmission by belt and of transmission crank by belt.

At the beginning of the Industrial Revolution in England, during the seventeenth century, the first lathes capable of machining a metal piece appeared.

Occasionally, lathes are classified, based on their use: workshop lathes, copying lathes, serial production lathes.

PARALLEL CAST-IRON LATHE HELLER, MODELO CE 460×1000

Based on their structural and functional characteristics, they can be classified as:

Parallel (mechanical/electronic) lathe:

From the old lathes, through the addition of new equipment, it became one of the most versatile machine tools. Currently, this type of lathe is an essential part of apprentices, workshops and maintenance workshops.

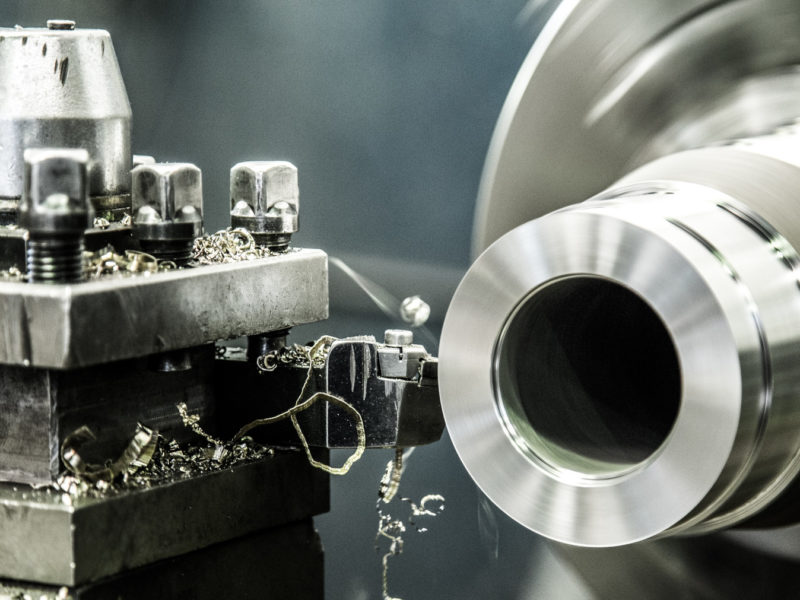

Its name is based on the parallelism that exists between the axis of the head (and therefore of the piece that is going to be machined) and the main trajectory of the machining tool. It consists of a head, inside which the spindle rotates, and two longitudinal cranes and parallel to each other and to the spindle. On the end of the spindle (neck) is mounted the universal plate, the plate with three claws or the point used to center the piece to be machined and communicate the turning movement provided by the electric motor through the change of speeds.

Between the heads, the tool carrier carriage moves; either manually with a handwheel or by means of the advance movement that communicates the rotation of the cylinder bar or that of the rod or screw of threading, both moved by the motor through the box of advances or the threaded.

On the trolley and perpendicular to the guides, the tool turret can be moved, guided and driven manually, through a steering wheel and a threaded spindle, or mechanically, thanks to the forward movement that the cylinder bar communicates.

Parallel electonic lathe FOLLOW. Modelo CE660V x 1500

Copying lathe:

Operates with a hydraulic and electronic device allows the turning of pieces according to the characteristics of the same following the profile of a template that reproduces a replica.

It is necessary to have a tool that allows well the evacuation of the chip and a system of lubrication and effective cooling of the cutting edge of the tools by abundant cutting oil or taladrina.

.Electronic copying lathe

Capstan lathe:

Its use is intended for the machining of pieces on which the simultaneous work of several tools is possible in order to reduce the total machining time.

The revolver lathe carries a trolley with a rotating turret in which the different tools that perform the machining of the piece are inserted. Parts can also be machined individually, fixing them to a hydraulically operated claw plate.

Capstan lathe

Automatic lathe:

It is called automatic lathe to a type of lathe whose working process is entirely automated. The feeding of the bar required for each piece is also done automatically, from a long bar that is inserted by a tube that has the head and is held by hydraulic clamping tweezers.

These lathes can carry one or more spindles.

- The ones of a single spindle are used for the mechanized of small pieces that require big series of production.

- Multi-spindle lathes, are very useful for machining larger parts, where in a programmed way, each spindle performs a part of the machining of the piece. The change of position of the spindles, allows a fast final, when working simultaneously.

Multi-spindle automatic lathe operation

Vertical lathe

Its use is intended for the machining of large pieces, which are subject to the plate of claws or other operators and whose size or weight would make it difficult to hold on a horizontal lathe.

They do not present counterpoint, but the only point of subjection of the pieces is the horizontal plate on which they are supported. The movement of the work piece to fix it to the plate is done using bridge cranes or hoists.

The axis of the spindle of the fixed head is vertical and the plate on it spins in a horizontal plane. The guides are mounted on two vertical and parallel columns, joined at the top by a bridge. The tool carriage moves horizontally on a bridge that in turn is guided by two columns.

CNC lathe

It offers a great capacity of production and precision in the machining.

It allows precise machining of curved surfaces, coordinating the axial and radial movements for the advancement of the tool.

The rotation speed of the workpiece head, the advance of the longitudinal and transversal trolleys and the execution dimensions of the part are programmed and, therefore, free of errors attributable to the machine operator.

CNC parallel lathe FOLLOW. Model CNC80

Recent Comments